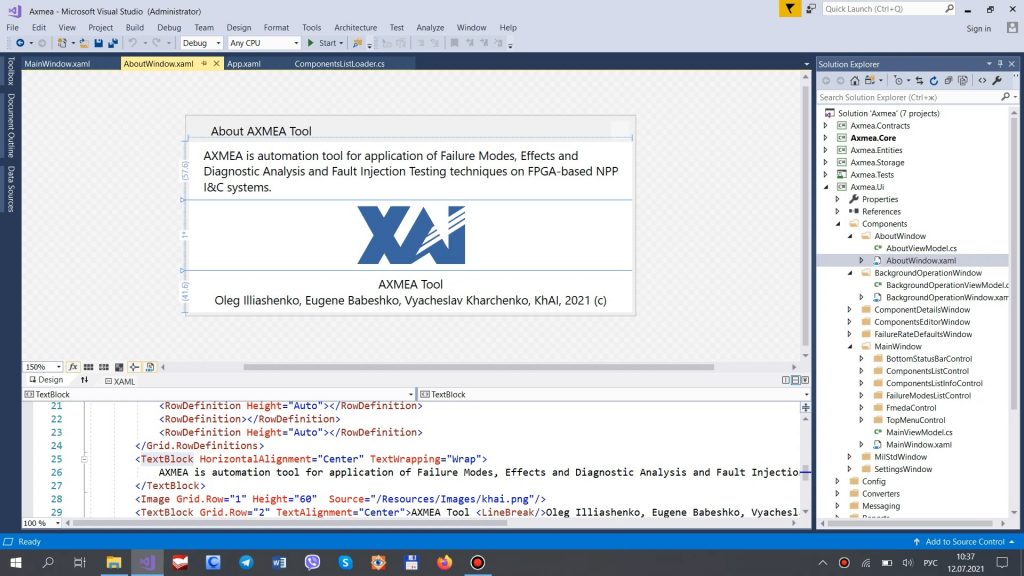

Reliability and safety assessment of modern complex systems that include thousands of electronic components becomes a tedious procedure that almost can’t be implemented manually without tool support. AXMEA tool is intended to support, simplify and make more credible the preceding assessment procedure.

AXMEA automates reliability and safety assessment using failure modes, effects, and diagnostic analysis (FMEDA) and provides user possibility to utilize different failure sources, specify their priorities, assign failure rates for electronic components and obtain required reliability and safety metrics. Tool is intended to simplify analysis of modern complex electronic systems and minimize influence of expert judgments. AXMEA supports usage of templates for input information (such as bills of materials with pre-defined structure, export information from electronic design software etc.) and output information (projects, reports with configurable structure etc.).

All known components are assigned failure rates by AXMEA automatically from different configured failure rate sources. Database of failure rates could be updated cumulatively by users from project to project, but basic database already contains failure rates of components appropriate to the following international normative documents supplied as AXMEA modules:

- MIL-HDBK-217F “Military Handbook Reliability Prediction of Electronic Equipment”. This module establishes and maintains consistent and uniform methods for estimating the inherent reliability of electronic equipment and systems, providing a common basis for reliability predictions during acquisition programs for complex electronic systems and equipment. It also establishes a common basis for comparing and evaluating reliability predictions of related or competitive designs;

- IEC 62380 “Reliability data handbook - Universal model for reliability prediction of electronics components, PCBs and equipment”. This module provides models for reliability prediction of electronic components, optical cards, printed circuit boards and equipment, which takes directly into account the influence of the environment. IEC 61709 “Electric components - Reliability - Reference conditions for failure rates and stress models for conversion”, the follower of IEC 62380, is also taken into account. Module considers guidance on the use of failure rate data for reliability prediction of electric components used in equipment. Implemented method uses the concept of reference conditions which are the typical values of stresses that are observed by components in the majority of applications. Reference conditions are useful since they provide a known standard basis from which failure rates can be modified to account for differences in the environment from the environments taken as reference conditions. The implemented prediction methodology assumes that the parts are being used within their useful life.

AXMEA accounts that each component may have one or more failure modes. Each type of failure must be classified according to IEC 61508 as safe detected, safe undetected, dangerous detected, dangerous undetected. Default classification of failures into dangerous undetected (or any other type specified by user) is supported.

Basic safety and reliability metrics provided by AXMEA include failure rates classified according to IEC61508 requirements, safe failure fraction, diagnostic coverage, safety integrity level.

AXMEA provides possibility to generate reports on the work performed according to configurable templates that could be used as relevant project reliability and safety documentation. Reports include all obtained metrics, used failure source database and assessment process steps.

If you wish to know more about AXMEA, watch the demonstration video on ECHO's YouTube channel here: